When turning metal on a lathe, the speed of the workpiece is quite important. Too slow and you tend to get a rough cut, too fast and the material work hardens.

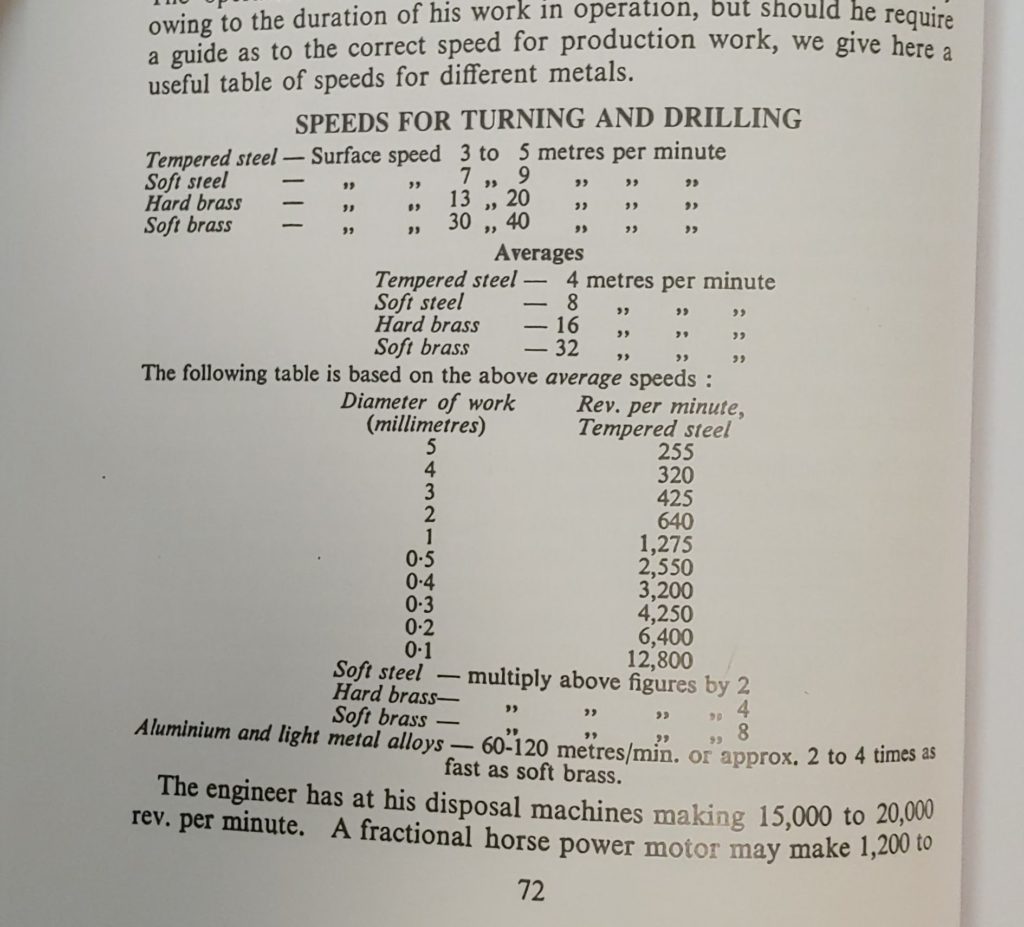

In Donald de Carle’s The Watchmaker’s and Model Engineer’s Lathe: A Users Manual, de Carle presents a table of recommended speeds for turning different metals.

The lathe motor that I have seems to run (as measured by a handheld tachometer) between 0-6000rpm and has very low torque at the lower speeds. Some speed adjustment was possible right away with the cone pulleys on each. The below table shows the (calculated) gear ratios for each belt position.

| Lathe Pulley vs Motor Pulley | 20mm | 24mm | 26mm |

| 32mm | 1.6:1 | 1.3:1 | 1.2:1 |

| 42mm | 2.1:1 | 1.75:1 | 1.6:1 |

| 52mm | 2.6:1 | 2.2:1 | 2:1 |

| 62mm | 3.1:1 | 2.6:1 | 2.3:1 |

Based on the table above and my first attempts at turning a winding stem, I needed to gear down my lathe a bit more in order to spin the workpiece at the right speed and stay within a decent part of the torque curve for my motor. In order to accomplish this, I ended up purchasing a 16mm pulley, a 58mm pulley, a few 8mm stainless rods and some pillow block ball bearings. This was expected to provide a 3.6x reduction in speed between the motor shaft and the countershaft. Further adjustments could be made using the original cone pulley’s on the lathe and motor.

Once installed, I tested the setup and measured the following ratios

| Belt Position on Pulleys | Motor Speed | Spindle Speed | Measured Ratio |

|---|---|---|---|

| 62mm:20mm | 3900 | 290 | 13.4:1 |

| 52mm:24mm | 4000 | 415 | 9.6:1 |

| 42mm:26mm | 4000 | 600 | 6.6:1 |

| 30mm:26mm | 4000 | 700 | 5.7:1 |

The real ratios are off a bit, perhaps due to measurements that weren’t perfectly precise, but it’s not too far off. If anything this new pulley may be a little aggressive and I might have been better of going with the 48mm one instead.